Site Search

Search within product

第751号 2023 (R05) .06発行

Click here for PDF version

農業と科学 令和5年6月

本号の内容

§肥料殻の流出を防ぐためのIB肥料や

崩壊性被覆肥料(Jコート)による被覆肥料代替効果の検証

Ehime Prefectural Institute of Agriculture, Forestry and Fisheries

黒瀬 咲弥

森重 陽子

§ In asparagus cultivation with coated urea fertilizer

窒素を3割減肥できる環境負荷低減施肥技術

Kumamoto Prefectural Agricultural Research Center, Production Environment Research Institute

Soil Environment Laboratory

山下 瑛

No § Soil - No.22

The role of soil in nurturing life on earth and preserving the global environment

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

IB fertilizers to prevent runoff of fertilizer shells and

崩壊性被覆肥料(Jコート)による被覆肥料代替効果の検証

Ehime Prefectural Institute of Agriculture, Forestry and Fisheries

黒瀬 咲弥

森重 陽子

Introduction

The leaching rate of fertilizer components is controlled by the characteristics of the coating material and is affected by soil temperature, soil moisture, and other factors. Although the film has photodisintegrative properties, it takes time to decompose in the natural environment, and it has been pointed out that the hollow film of fertilizer shells that have finished leaching may float during paddling (Kobayashi, 2015), and there is concern that they may run off into the water system (Japan Ammonia Fertilizer Association and National Compound Fertilizer Industry Association, 2019).

To reduce the film of coated fertilizers that run off into the water system, synthetic slow-release fertilizers can be substituted or the disintegration of the film can be improved. Among synthetic slow-release fertilizers, isobutyraldehyde condensed urea (IB) fertilizers are mainly degraded by hydrolysis, and their leaching is controlled to a certain extent by particle size, but their leaching control is inferior to that of coated fertilizers. On the other hand, J-coat is a coated fertilizer with enhanced photo-disintegration compared to existing coatings, and its disintegration by physical factors such as tillage has been reported to be higher than that of LP-coat (Matsuda, 2021; Matsunaga and Shiratori, 2019; Kawashima, 2019).

Therefore, in this study, we clarified the effect of replacing LP coat, the raw material of conventional one-shot fertilizer formulations, with IB fertilizer or J coat on the growth yield of paddy rice plants, and examined the disintegration and leaching patterns of the J coat film in the paddy fields.

2. Methods

(1) Field test

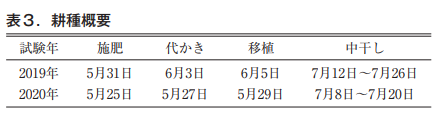

The trial was conducted in paddy field plots in the Ehime Prefectural Institute of Agriculture, Forestry and Fisheries during 2019-2020. 'Akidawara' was used as the test seed.

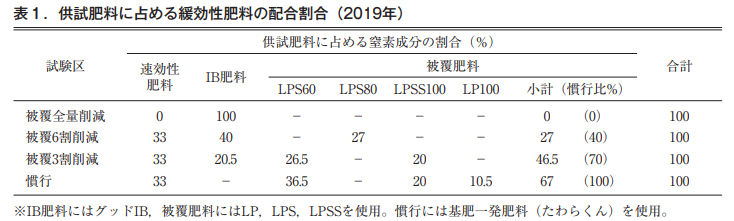

In the 2019 trial, the conventional zone was the zone using a commercial one-shot base fertilizer (trade name: Tawarakun) with LP Coat as the compounding material, and the following four zones were selected: a total coverage reduction zone where all LP Coat was replaced with IB fertilizer, a 60% coverage reduction zone where 60% of LP Coat was replaced with IB fertilizer, and a 30% coverage reduction zone where 30% of LP Coat was replaced with IB fertilizer as well (Table 1). The four plots were divided into two types of plots (Table 1). To keep the fertilizer efficacy pattern as similar as possible, Good IB, which leaches in about 40 to 60 days, was used for the other IB fertilizers, and LPS60, LPS80, and LPSS100 were combined for the LP coat, and four replications were installed in each plot.

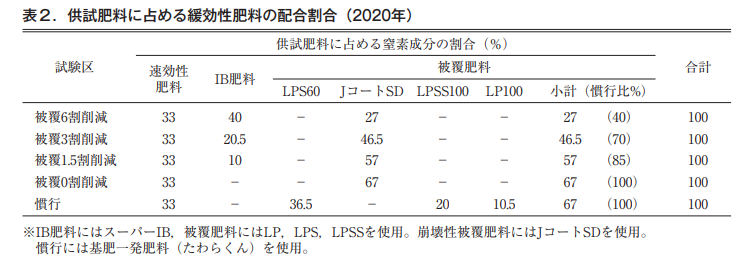

In the 2020 trial, the conventional plot was the same as the previous year, and J-Coat SD (a sigmoidal, disintegrating, coated fertilizer with 80% leaching at 25°C for about 80 days) was used as the coated fertilizer in all other plots instead of LP-Coat. In addition, there were five compartments with 60% coverage reduction, 30% coverage reduction, 1.50% coverage reduction, and 0% coverage reduction, according to the ratio of J-coat replaced by IB fertilizer (Table 2).

In order to keep the fertilization pattern of each plot as similar as possible, Super IB fertilizer, which leaches in about 80 to 100 days, was used as IB fertilizer in this year, and three replications were installed in each plot. The amount of fertilizer applied was 12 kg N/10a for all plots in 2019 and 14 kg N/10a for all plots in 2020. Fertilizer application and other cultivation practices are summarized in Table 3, with transplanting of young seedlings in both years at a planting density of 18.2 plants/m2.

(2) Investigation of the characteristics of coated fertilizers

The test was conducted in 2020. 3 LP coats (LPS60, LPSS100, LP100) and 2 J coats (J Coat SD, J Coat SE (80% elution at 25°C for about 100 days)) were embedded in rice paddy fields at Ehime Prefectural Institute of Agriculture, Forestry and Fisheries to investigate nitrogen elution rate and film collapse. A polyethylene mesh bag containing 2.5 g of each sample was buried at a depth of 5 cm from the surface of the rice field on May 27. Nitrogen leaching rate was sampled five times until September 10, and nitrogen analysis was performed by JCAM Agri Co.

The samples after 261 days were photographed immediately after removal from the mesh bag, and the samples after 352 days were evaluated on a 6-point scale for the degree of collapse when pressed with the finger. The sample after 352 days was evaluated on a 6-point scale of disintegration when pressed with a finger. The study consisted of three replicates of 30 samples.

The soil temperature of the plots was measured hourly at a depth of 5 cm with a temperature recorder (T&D TR-71wf) from the time of burial to the time of tsubo harvesting.

Results and Discussion

(1) Weather and ground temperature

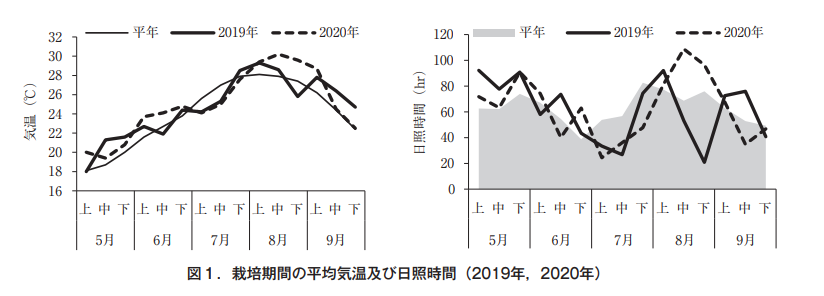

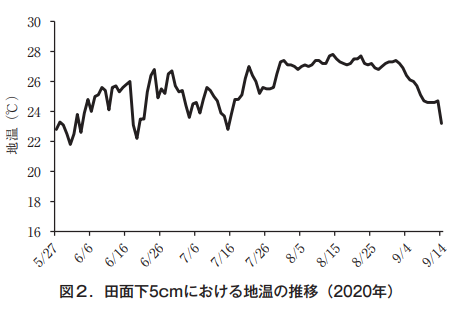

Temperatures during the growing season were 0.8°C below normal in July, normal in August, and 2°C above normal in September in 2019; in 2020 they were 1.3°C below normal in July and 2°C above normal from August to early September. Sunshine hours were shorter than normal in 2019 with 701 TP3T in July and 511 TP3T in mid- to late August compared to the normal, and in 2020 with 561 TP3T in July and 1241 TP3T in August to early September compared to the normal (Figure 1). The average soil temperature during the growing season was 25.6°C (Figure 2).

(2) Growth and yield of 'Akidawara' with a one-shot basal fertilizer that replaced coated fertilizer with IB fertilizer

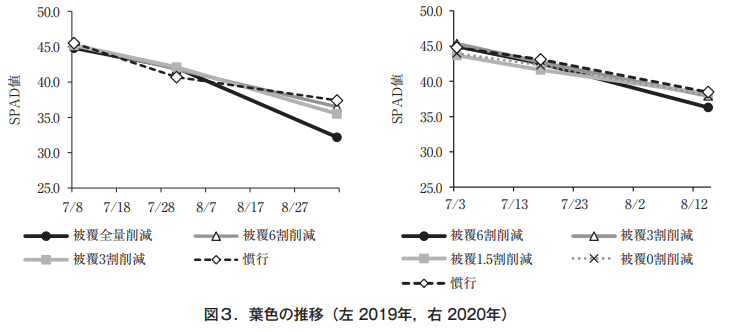

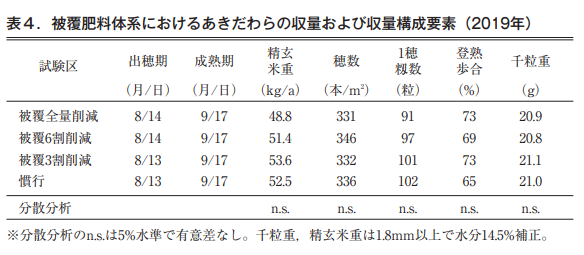

In 2019, leaf color in July was similar in all test plots, but was lower in the reduced total cover plot at 9/5 after ear emergence (Figure 3).

Yield and yield components and brown rice quality were not significantly different among the test sections, but the number of ears per ear tended to decrease as the percentage of reduced fertilizer coverage increased. The number of ears per ear was slightly lower and the weight of milled brown rice was the lightest in the total reduction area (Table 4).

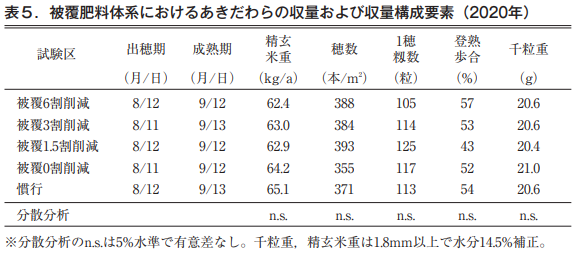

In 2020, leaf color was slightly darker in the 60% and 30% reduced cover areas at 7/3, and there was no difference among the trial areas after 7/17 (Figure 3). The number of ears was the lowest in the 60% reduction area with the highest reduction rate of fertilizer cover, and the weight of milled brown rice was the lightest in the 60% reduction area (Table 5).

In conclusion, there was no significant difference in the yield of ʻAkidawara' in each test plot in 2019 when LP coat was replaced by IB fertilizer at a replacement rate of 10-30%. In 2020, when J-coat was used as a coated fertilizer and 60 to 1.5 percent was replaced with IB fertilizer, the yield of ʻAkidawara' was similar to that of the previous year.

However, when all the fertilizer was substituted in 2019, the leaf color after ear emergence was lighter and the number of ears per ear佅 tended to be lower when the reduction ratio of coated fertilizer was more than 60% in both years. Therefore, it was concluded that the replacement ratio should not exceed 60% in order to obtain stable growth yield by replacing coated fertilizer with IB fertilizer.

(3) Nitrogen leaching and film collapse of coated fertilizers

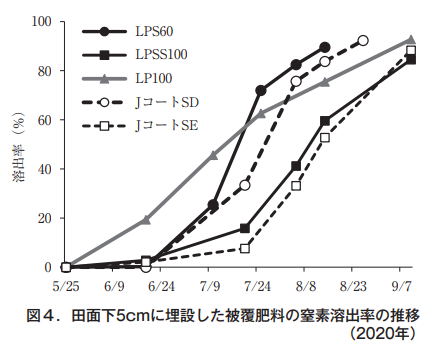

The nitrogen elution rate reached 80% in 70 days for LPS60, 104 days for LPSS100, 88 days for LP100, 78 days for J-coat SD, and 102 days for J-coat SE after burial (Figure 4), indicating that each fertilizer eluted almost as designed. and LPS60 were similar, and J-Coat SE and LPSS100 were almost equivalent.

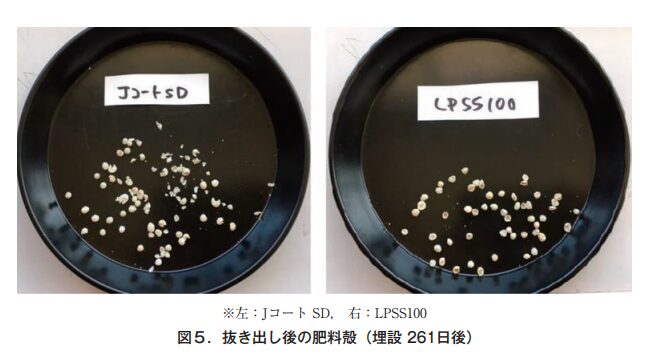

After 261 days of burial, some cracks were observed in the J-Coat SD, but the LPSS100 retained its original shape (Figure 5).

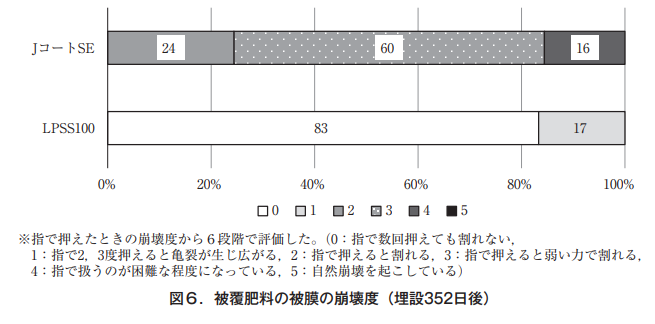

After 352 days of burial, J-Coat SE showed cracking or collapse of the coating, while LPSS100 showed "no cracking when pressed with a finger" to "cracking and spreading when pressed several times" (Figure 6).

Based on the above, it is considered that J-coat has higher collapsibility of the film after the end of rice cultivation than LP-coat, and that the film collapses after the end of cultivation or by impacts such as plowing in preparation for the next crop, resulting in less floating of the film of fertilizer shells from the next crop onward.

Summary

Since the leaching stability of the nitrogen component of J-coat, a collapsible coated fertilizer, was equivalent to that of LP-coat, it was considered possible to replace LP-coat with J-coat as a coated fertilizer as a blending material for rice one-shot fertilizers. In addition, J-coat has high collapsibility of the film (fertilizer shell) after paddy rice cultivation, and it is thought that the film will be less likely to float up when the next crop is plowed.

We replaced some or all of these coated fertilizers with IB fertilizers, which are synthetic slow-release fertilizers, and investigated the optimum replacement ratio for ʻAkidawara'. Therefore, it seems possible to replace the entire crop at maximum. However, the leaf color after ear emergence was light when the replacement rate was 10%, and the number of ears was low when the replacement rate was 10 to 60%, suggesting that the replacement rate of IB fertilizer should not exceed 60% to obtain stable growth yields.

Based on the results of this study, it is expected that the use of one-shot base fertilizers made from IB fertilizer or J-coat as a substitute for LP-coat in rice cultivation will reduce the amount of coated fertilizer film (fertilizer shell) that runs off into the water system, thereby reducing the environmental impact of the fertilizer.

References

●小林新(2015):

樹脂系被覆肥料による革新的な施肥技術の開発と今後の展望6.

樹脂系被覆肥料に期待される新たな機能と施肥技術への展望,

日本土壌肥料学雑誌,86(6),563-572.

●日本肥料アンモニア協会・全国複合肥料工業会(2019):

海洋漂着プラスチックを巡る肥料業界の対応について,

●松田英樹(2021):

被覆肥料「Jコート」の水稲に対する全量基肥施用の効果と被膜崩壊性,

農業と科学,732,1-4.

●松永真,白鳥孝太郎(2019):

新型被膜でコーテングされた水稲一発肥料Jコートの実用性の検討,

農業と科学,707,8-12.

●川島寛(2019):

被覆尿素肥料(Jコート)を用いた水稲の生育収量と被膜の崩壊程度,

農業と科学,710,1-5.

Coated urea fertilizer in asparagus cultivation

窒素を3割減肥できる環境負荷低減施肥技術

Kumamoto Prefectural Agricultural Research Center, Production Environment Research Institute

Soil Environment Laboratory

山下 瑛

Introduction

In Kumamoto Prefecture, asparagus is mainly grown in greenhouses as a semi-promoted, long-term crop, with a planted area of 99 ha in 2020 and still increasing. This is because the unit sales price of asparagus is higher and more stable than that of other vegetable crops, many farmers switch from other crops for this reason, harvesting is relatively light work, and sorting and other facilities are well developed.

Asparagus is usually cultivated with high fertilizer application. In Kumamoto Prefecture, the customary amount of nitrogen fertilizer applied is about 50 kg/10a per year, which is considerably higher than that of other vegetables. In addition, in order to ensure the yield and quality of asparagus, 2 to 4 tons of cattle manure is applied per 10a per year. The application of fertilizers and compost to asparagus production fields results in excess nitrogen, and there is concern about groundwater contamination due to leaching of nitrate-form nitrogen.

To solve this problem, Kumamoto Prefecture has enacted an ordinance to promote agriculture that nurtures groundwater and soil, and is working to spread and promote environmentally friendly agriculture. In asparagus cultivation, there is an urgent need to establish fertilizer application technology that reduces the environmental impact of applied nitrogen.

In order to establish a technology to reduce the amount of nitrogen fertilizer applied while maintaining the yield and quality of asparagus, we investigated fertilization technology using a coated urea fertilizer (LP coat), which is considered to have a high nitrogen utilization rate.

2. Testing Method

(1) Composition of the test area

Asparagus (variety: Welkam) was grown in a greenhouse at the Production and Environmental Research Institute, Kumamoto Agricultural Research Center for two years from 2020 to 2021. The soil was a multi humic thick-layered black box soil.

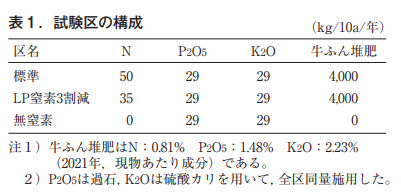

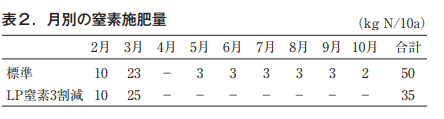

The composition of the test plots is shown in Table 1. The standard conventional plot was fertilized eight times with urea at an annual nitrogen fertilizer rate of 50 kg/10a (Table 2).

In contrast, in the LP nitrogen reduced by 30%, the annual nitrogen fertilizer amount was reduced by 30% to 35 kg/10 a. In the standard zone, sigmoidal LP Coat S40 (LPS40) was applied at 10 kg/10 a of nitrogen before the start of heat retention (February) and linear LP Coat 14 (LP140) at 25 kg/10 a of nitrogen at the start of the standing stems (March). Linear LP Coat 14 (LP140) was applied twice at 25 kg/ 10 a of nitrogen component at the beginning of the standing stem (March).

Fertilizer was applied to the surface of both test plots and mixed lightly with the soil. In February, 4 t/10a of cattle manure was commonly applied in both composting areas. In addition, a nitrogen-free area was established. The test was conducted in three replications of 11.52 m2/area.

(2) Determination of nitrogen elution of LP coat

A fertilizer burial test was conducted to determine the amount of nitrogen leached from the LP coat. In this test, 2.5 g of LPS40 or LP140 was placed in a mesh bag and buried in the crop soil in an asparagus growing house in triplicate. The urea remaining in the mesh bags without leaching was colorimetrically determined by the dimethylaminobenzaldehyde method, and the amount of nitrogen leached was calculated. The burial period of LPS40 was from February 6 to July 27, 2020, and that of LP140 was from March 16 to December 25, 2020.

(3) Cultivation test

Asparagus was cultivated according to the cultivar outline shown in Table 3, and young stalks were harvested periodically to determine yield and quality. Nitrogen absorption was determined by measuring the nitrogen content of the harvested young stalks, pseudo-leaves removed during the growing period, and stems and leaves at the time of total harvesting.

(4) Determination of inorganic nitrogen in soil

During the asparagus cultivation period, crop soil and subsoil were sampled to determine the amount of inorganic nitrogen in the soil at different growing seasons.

Results and Discussion

(1) Nitrogen elution pattern from LP coat

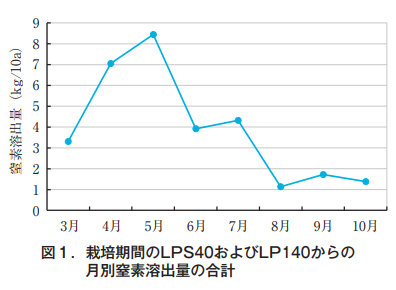

The monthly total amount of nitrogen leached from the sigmoidal coated urea fertilizer, LPS40, and the linear type, LP140, is shown in Figure 1. The graph shows that the total amount of nitrogen leached from the coated fertilizers increased from March to May, and then gradually decreased. The time when the amount of nitrogen leached from the LP coat increased coincided with the period of standing stalks of asparagus, suggesting that nitrogen was effectively supplied in response to the growth of asparagus.

(2) Yield and quality

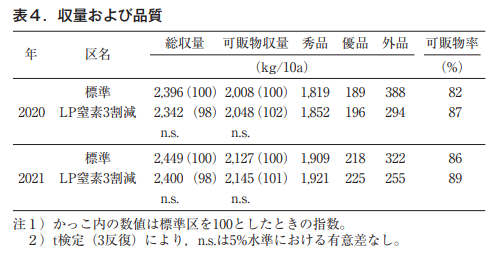

Asparagus yields and quality are shown in Table 4.

The total annual yield of young stems was 2342 kg/10a in 2020 and 2400 kg/10a in 2021 in the 30% LP nitrogen-reduced area, about 2% lower than 2396 kg/10a and 2449 kg/10a in the standard area, respectively, but these results were not statistically significant and were considered to be equivalent. The yields of saleable products were 2048 and 2145 kg/10a in the 30% LP nitrogen-reduced zone and 2008 and 2127 kg/10a in the standard zone, respectively, which were slightly higher in the 30% LP nitrogen-reduced zone, but again, no statistically significant differences were observed.

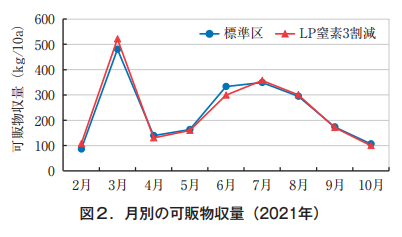

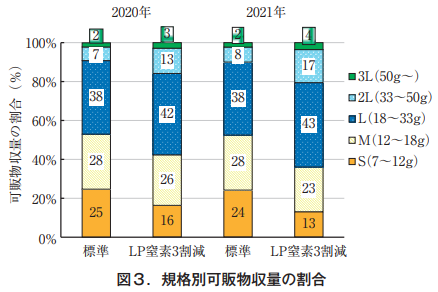

The monthly yield of saleable products in Figure 2 was almost the same in the standard and the 30% reduction of LP nitrogen, but the percentage of saleable products, a quality-related trait, was 3-51 TP3T higher in the 30% reduction of LP nitrogen, and the percentage of superior and excellent products also tended to increase in the standard. On the other hand, the percentage of saleable products by standard trait ranged from 47 to 481 TP3T in the standard zone, while it was 58 to 641 TP3T in the zone with 30% reduction of LP nitrogen, more than 10 points higher (Fig. 3).

Thus, there was almost no difference in asparagus yield between the standard and the 30% reduction in LP nitrogen, but the ratio of saleable and superior products and the ratio of L-class products or higher were clearly higher in the 30% reduction in LP nitrogen. It is well known that the nitrogen requirement of asparagus is higher during the standing shoot stage. As shown in Figure 1, it is interpreted that the increased nitrogen supply from the LP coat during the standing shoot stage satisfied the nitrogen requirement of asparagus and led to the improvement of quality-related traits such as the percentage of saleable products and the percentage of L-class or better products.

(3) Inorganic nitrogen content and nitrogen balance in soil

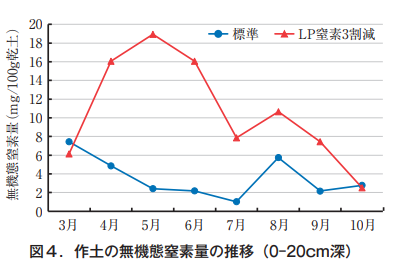

The amount of inorganic nitrogen in the crop soil remained higher in the 30% LP nitrogen reduction zone than in the standard zone (Figure 4).

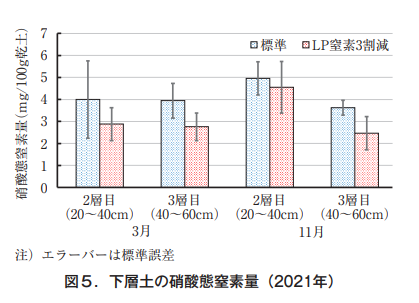

This reflects the fact that the total nitrogen leaching of LPS40 and LP140 in Figure 3 increases significantly from March to May. In contrast, in the standard zone, fertilized urea is quickly nitrified to nitrate nitrogen, which is easily leached downward by watering. Therefore, the amount of nitrate-nitrogen in the subsoil is estimated to be slightly higher than that in the 30% LP nitrogen reduction area (Figure 5).

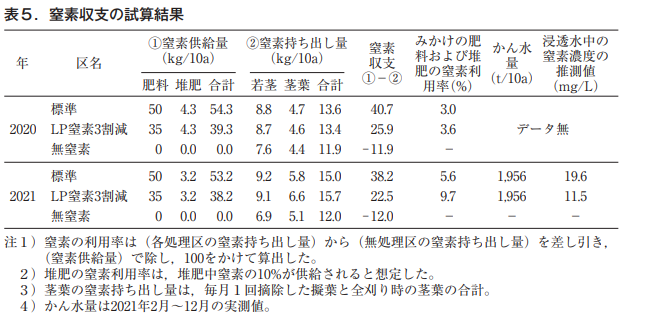

To see whether fertilizer nitrogen is efficiently absorbed by asparagus, it is useful to examine the nitrogen balance. According to the trial calculation results shown in Table 5, the amount of nitrogen taken up by asparagus (total amount of nitrogen absorbed by young stems and leaves) in the 30% LP nitrogen reduction area varied from year to year, but ranged from 13.4 to 15.7 kg/10a, which was almost the same as the 13.6 to 15.0 kg/10a of the standard area.

The nitrogen balance obtained by subtracting the amount of nitrogen taken out from the nitrogen input (nitrogen derived from fertilizer and compost) was 14.8 to 15.7 kg/10a lower in the LP nitrogen reduced by 30% zone than in the standard zone, and the utilization rate of fertilizer and compost was also higher, taking the nitrogen-free zone into account. This suggests that the fertilizer application method using LP coat is a method that reduces excess nitrogen supply and prevents excess nitrogen from remaining in the soil.

The nitrogen balance corresponds to the amount of nitrogen remaining in the soil that is not absorbed by asparagus (Table 5).

This value divided by the amount of irrigation water used during the asparagus cultivation period is considered to give an estimated value of nitrogen concentration in permeate water. This value was 11.5 mg/L in the LP nitrogen 30% reduction zone, which was considerably lower than the 19.6 mg/L in the standard zone.

(4) Production costs and profitability

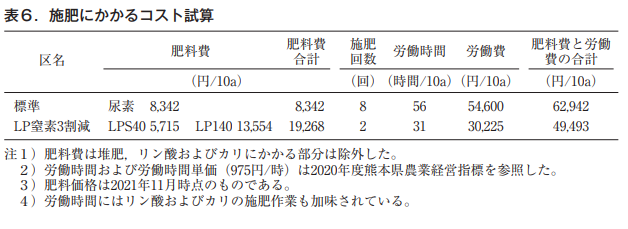

The fertilizer cost in the 30% nitrogen-reduced zone using LP coat was lower than that of the standard fertilizer using urea.

This is more than two times higher than the cost of fertilizer. However, since the number of fertilizer applications is reduced to one-fourth, labor costs for fertilizer application are lower, resulting in a total cost reduction of about 13,000 yen in fertilizer and labor costs (Table 6).

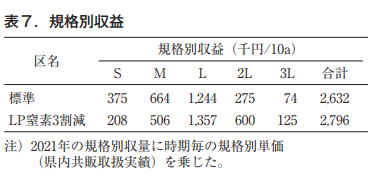

When profitability is calculated by multiplying the monthly yield by standard by the unit sales price per standard, it is estimated that the 30% reduction in LP nitrogen increases the supply of nitrogen during the standing stem period, which results in a large proportion of L-class or higher products with high unit sales price. The profit of the standard zone is estimated to be 2,796,000 yen per 10a, which is 164,000 yen higher than the profit of the standard zone (Table 7).

Summary

Based on these results, it can be concluded that the method of applying LPS40 at 10 kg/10 a of nitrogen before the start of heat retention and LP140 at 25 kg/10 a of nitrogen at the beginning of the first stage of the shoots in semi-promoted, long-duration asparagus cultivation is an environmentally friendly fertilization technique that reduces nitrogen by 30% compared with the standard fertilization method (50 kg/10 a of nitrogen applied annually), but still produces the same yield, is profitable, and reduces costs. It is concluded that this method is an environmentally friendly fertilizer application technique that reduces leaching of nitrate nitrogen, while providing the same yield and cost savings, even with a 30% reduction in nitrogen compared to the standard fertilization method (annual nitrogen fertilization of 50 kg/10a).

When utilizing the fertilization technology using coated urea fertilizer for asparagus introduced in this report, the following points should be considered when applying fertilizer in agricultural fields.

Since surface application of LP coat tends to delay nitrogen leaching, mixing with soil is necessary to achieve the expected nitrogen leaching (Kumamoto Agricultural Research Report No. 939, 2021). However, asparagus is a perennial crop, and it is difficult to mix the LP coat with the soil on the swell using a control machine. This is especially true after the young stalks have begun to grow.

Therefore, before the start of heat retention, fertilizer is applied by first dropping the top soil between the swells and then applying fertilizer and compost to the soil. Next, the soil dropped between the swells is reapplied to the top of the swell using a tiller. For fertilizer application at the beginning of the stand, fertilizer or compost is applied to the top of the swell, and the soil in the aisles is then covered by the tiller to cover the fertilizer. In all cases, however, it is assumed that a sufficient amount of soil is available.

No Soil - No. 22

The role of soil in nurturing life on earth and preserving the global environment

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

In the last issue, I spoke about the creatures in the soil. However, the soil does not provide a living place only for soil creatures. All of life on the earth's land surface benefits directly or indirectly from the soil. This can be understood from the fact that many lives are nourished by the food chain of "predator (eat) - prey (be eaten)" on the earth, starting from plants growing in the soil. It also plays a major role in preserving the global environment, which is the living environment for terrestrial organisms.

In this article, I would like to consider these important functions of soil.

1. three major functions of soil

An overview of the functions of soil brings to mind the foundation of roads, railroads, and buildings, raw materials for various construction materials and ceramics, and a constituent factor of the landscape. However, there are more important functions than these, such as (1) growing plants on land (production function), (2) holding water (water retention function), and (3) decomposing and purifying organic matter and chemical substances (decomposition and purification function), which support life on the ground.

(1) Function of growing plants on land (production function)

Plants receive heat and light from the sun, carbon dioxide from the atmosphere, and water from the soil for photosynthesis. This plant is the starting point of food for at least all terrestrial organisms. The food of the creatures in the soil is also originally organic matter produced by plants. Carnivores are also able to eat meat because herbivores live on plants. Since the soil supports the growth of plants, the productive function of the soil is extremely important for terrestrial organisms.

In some cases, crops are grown hydroponically or otherwise, without using soil, by artificially controlling light, day length, temperature, and other aspects of the growing environment. Such facilities are sometimes referred to as plant factories (Figure 1).

These cultivation methods require large energy costs for facilities and machinery for nutrient management, as well as for heating, cooling, and lighting, and high maintenance and management costs, including labor. In addition, the spread of external pathogens and diseases during cultivation is much faster than with soil cultivation. Furthermore, it is unrealistic to leave food production to hydroponics, considering concerns about the sustainability of fossil energy. The dependence of terrestrial organisms on soil for food production is unlikely to change in the future.

(2) Function to retain water (water retention function)

When the soil is covered with asphalt-paved urban streets and concrete buildings, much of the rainwater does not percolate into the soil, but instead flows directly into rivers through the sewage system. Under these conditions, when temporary heavy rains occur, small urban rivers overflow and cause damage. This is because the soil has lost its function of holding water.

Phenomena resulting from a decrease in the water-holding capacity of the soil can be observed, for example, in residential land development on hillsides cleared from forests. At such sites, rainwater runs over the soil surface, scours the topsoil, and flows into rivers as a muddy stream. The 21st century is said to be the century of water problems (Postel, 2000). Freshwater resources are a limiting factor in agricultural food production, and there is no hope for increased production. This is not only because of the decline in the water-holding capacity of the soil, but also because the amount of water stored in aquifers is drastically decreasing due to the excessive use of water stored underground (underground aquifers). The water-holding capacity of the soil has a great impact on the future of life on earth, including us humans.

(3) Decompose and purify organic matter and chemical substances (decomposition and purification function)

In the last issue, I mentioned that organisms in the soil decompose organic matter, such as the remains of plants and animals and animal excrement.

This decomposition of organic matter creates a nutrient cycle.

Various hazardous organic wastes are also purified by decomposition processes in the soil. Microorganisms that degrade man-made chemicals such as petroleum components and organochlorine compounds such as trichloroethylene and polychlorinated biphenyls (PCBs), which are precursors of so-called environmental hormones that were once considered problematic, also live in the soil (Uchiyama, 1999). Bioremediation, or biological remediation, is the process of using the ability of microorganisms to decompose pollutants to purify and restore the environment, and is attracting attention as a safe remediation measure for environmental pollution.

However, the function of decomposition and purification of organic matter is not a function of the soil itself but a function derived from the biological activity of the soil.

2. soil supports and preserves the global environment

The Earth's environment is maintained by the smooth circulation of heat, energy, water, chemicals, and other materials between the atmosphere, biosphere, hydrosphere, and geosphere that make up the Earth's surface. Most of the transfer of materials and energy between these spheres takes place through the soil, which is the contact surface (interface).

The rate of movement of matter and energy in the soil controls the speed of that movement. The physical, chemical, and biological properties and functions of soil can change the flow of water, heat, and materials from a rapid state to a gentle state, and in some cases, they can be stored in the soil to inhibit the flow itself. The ability of soil to soften the rate of movement of materials (buffering capacity) is a fundamental factor in ensuring the harmonious and smooth circulation of materials and energy on the earth.

Since the 20th century, human activities have expanded on an unprecedented scale, adversely affecting the global environment. Unprincipled deforestation to expand arable land, massive consumption of fossil fuels to increase productivity, and other human activities have caused the flow of materials and energy to exceed the control of the soil. The resulting changes in the global environment have had adverse effects such as global warming, depletion of the ozone layer, desertification and salinization of the soil, soil erosion, water pollution, and reduction of biodiversity.

3. soil functions are threatened by 10

The phenomenon in which irreplaceable soil loses its productive function due to human activities is called soil degradation.

At the end of the 20th century, degraded land area amounted to 17% of above-ground vegetated land, or 2 billion hectares (United Nations Environment Programme, 1997); according to the World Soil Resources Report published in 2015 (FAO and Intergovernmental Panel on Soils = ITPS, 2015)

The "10 most serious threats to soil function" are

The threats in order of intensity are (1) soil erosion, (2) changes in organic carbon, (3) nutrient imbalance, (4) salt accumulation and sodiumification, (5) soil covering (covering soil with concrete, asphalt, etc. to inhibit permeability), (6) reduction of soil biodiversity, (7) soil contamination, (8) acidification, (9) soil compaction, (10) waterlogging (especially when the soil changes from an aerobic to a waterlogged condition). (especially when the soil changes from aerobic to waterlogged conditions).

Soil functions are being deprived by various threats and human activities. However, it is also true that proper management by farmers maintains the function of farmland soil (Figure 2).